Subs & Stabilizers

Crossover Subs

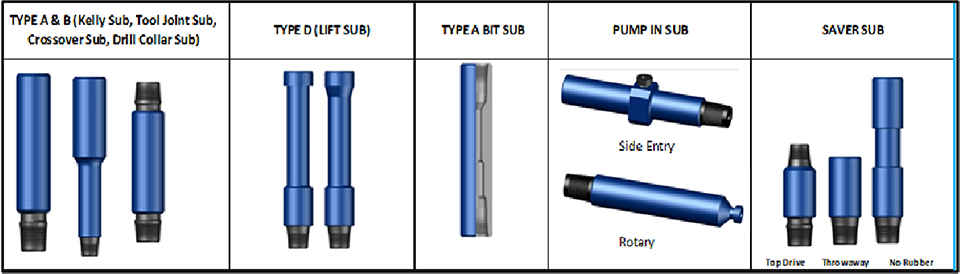

• All subs made by Hilong Abu Dhabi Machine Shop are API inspected and certified, or they may be new with mill certs.

• Subs are shorter components manufactured from AISI 4145H modified alloy, heat treated to BHN range of 285-341.All connections are phosphate and the threads are cold rolled. Normally they are of 36 or 48 inches in length.

• Bit subs or crossover subs are used to connect the drill bit to the first piece of BHA equipment or to crossover connections in the drill string. Drill bits are manufactured with a pin, making make-up impossible without a bit sub.

• Lift subs or handling subs are used to lift BHA components from the catwalk to the rig floor.

• Top drive subs or saver subs serve as the sacrificial element between the drill string and the top drive, reducing repair and maintenance costs.

• Workover subs or circulating subs are used to limit the allowable fluid-circulation rates to pass out of the drill string and into the bit but does not allow those fluids to back-flow into the drill string.

Stabilizers

• A drilling stabilizer is a piece of downhole equipment used in the bottom hole assembly (BHA) of a drill string. It mechanically stabilizes the BHA in the borehole in order to avoid unintentional sidetracking, vibrations, and ensure the quality of the hole being drilled.

• It is composed of a hollow cylindrical body and stabilizing blades, both made of high-strength steel. The blades can be either straight or spiraled, and are hard-faced for wear resistance