Sour Service Drill Pipe/Sour Service Heavyweight Drill Pipe

Brief Introduction

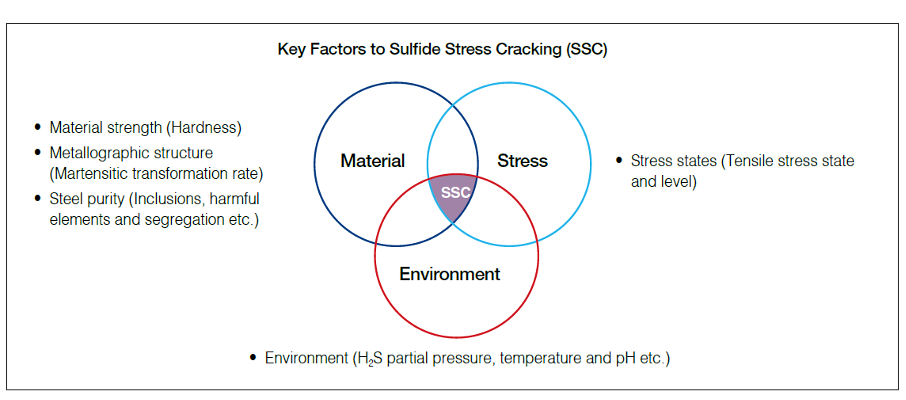

When drilling in an H2S environment, standard drill pipe is highly susceptible to sulfide stress cracking (SSC). Considering that SSC is extremely hazardous, the use of sour service drill pipe to ensure safe drilling in sulfur-containing environments is crucial.

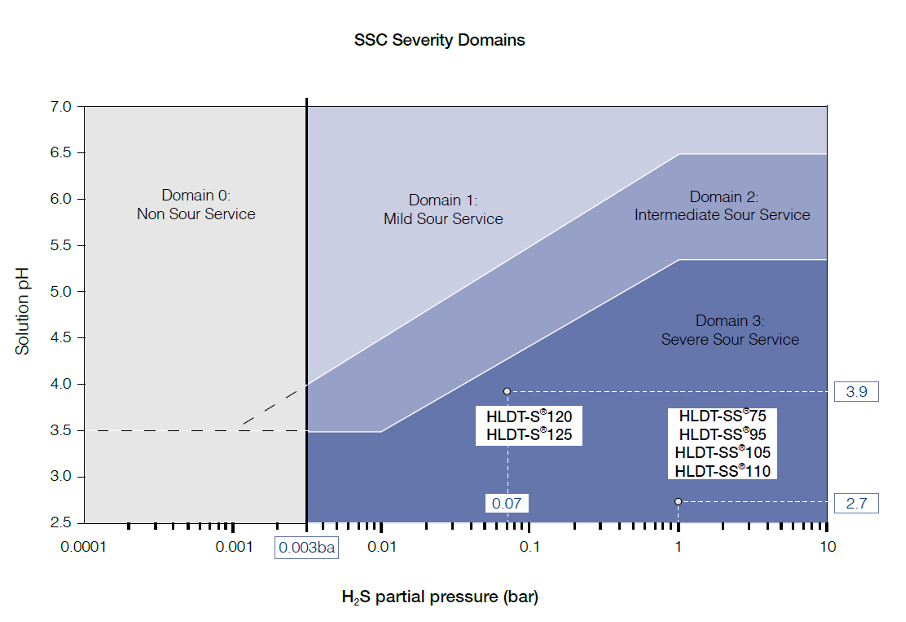

Sulfide stress cracking is directly related to the tensional stress load, drilling environment (H2S partial pressure, PH value, temperature, etc.); it is also related to the drill pipe material's SSC-resistant properties. Through the development of special drill pipe materials and manufacturing technologies, we improve the drill pipe's resistance to sulfide stress cracking. Meeting drilling requirements for various sulfur-containing wells has been the focus of Hilong's research and development for several years.

Hilong Sour Service Drill Pipe Product Sizes/Grades

• Hilong Sour Service Drill Pipe Sizes

2 3/8", 2 7/8", 3 1/2", 4", 4 1/2", 5", 5 1/2", 5 7/8", 6 5/8"

• Hilong Sour Service Drill Pipe Grades

HLDT-SS®75, HLDT-SS®95, HLDT-SS®105, HLDT-SS®110, HLDT-S®120, HLDT-S®125

Please refer to Table 7 in our viewable/downloadable DRILLING TOOLS BROCHURE.

Hilong Sour Service Heavyweight Drill Pipe Product Sizes/Grades

• Hilong Sour Service Heavyweight Drill Pipe Sizes

3 1/2", 4", 4 1/2", 5", 5 1/2", 5 7/8", 6 5/8"

• Hilong Sour Service Heavyweight Drill Pipe Grades

HLHW-SS®75 and HLHW-SS®90

Please refer to Table 8 in our viewable/downloadable DRILLING TOOLS BROCHURE.