Hilong Premium Connections

Hilong Double Shoulder Connection HLIDS® & HLMT® Series

HLIDS® is an API-compatible high-torque double-shoulder connection developed by Hilong.

HLMT® is a double-shoulder connection designed and developed for specific API connections and the customer's requirement on-site.

HLIDS® and HLMT® have features as follows:

- The same standard thread profile as API

- Double-shouldered design

- Smooth transmission on inside diameter

Product Advantages

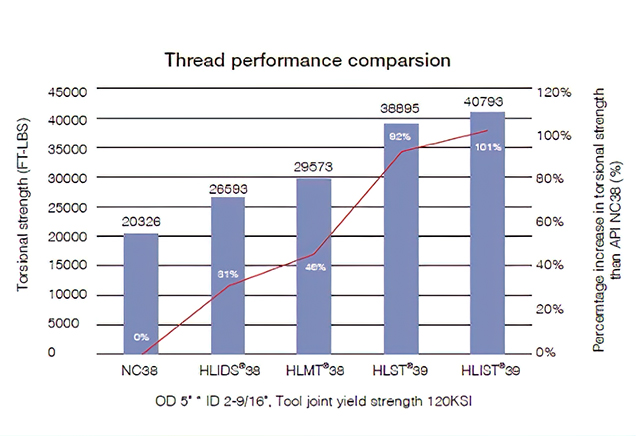

- Higher Torque: by using HLIDS® and HLMT® connections with current API ODs and IDs will result in 20% - 50% higher torque capacity than API.

- While maintaining required torsional strength, it can:

- minimize the tool joint OD

- maximize the ID

- High fatigue resistance, thus prolonging the pipe service life

- Improved hydraulic efficiency and washout reduction

Product Specifications

HLIDS® series includes HLIDS®23, HLIDS®26, HLIDS®31,HLIDS®38, HLIDS®40, HLIDS®46, HLIDS®50, HLIDS®5

1/2FH and HLIDS®6 5/8FH etc. and can be applied to all API drill pipes with standard steel grades and specifications from 2 3/8 to 6 5/8 inches.

For HLIDS® connection performance, Please see Table A.5 or Table B.5 in our DRILLING TOOLS BROCHURE.

HLMT® series includes HLMT®2-3/8PAC, HLMT®2-7/8PAC, HLMT®38, HLMT®40, HLMT®46, HLMT®50 and HLMT®5-1/2FH etc.

For HLMT® connection performance, Please see Table A.6 or Table B.6 in our DRILLING TOOLS BROCHURE.

HLIDS® and HLMT® Applicable Well Conditions

Suitable for drilling under harsh conditions such as deep well, horizontal well, extended-reach well and sulfur-containing environments.

Hilong Super High Torque Connection: HLST® & HLIST® Series

HLST® & HLIST® are new-generation super high-torque double-shoulder connections developed based on the structure of HLIDS®.

HLST® & HLIST® are more suitable used in deep-well drilling, ERD, HDD, sour service and critical well etc.

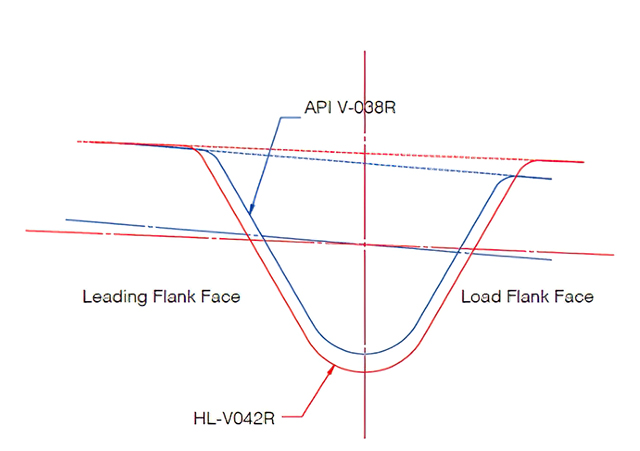

Comparing with API connection, HLST® & HLIST® have the following features:

- Improved double-shoulder structure

- Improved thread root radius designation

- Optimized thread pitch and taper

Product Advantages

- Super high-torional strength: 70% extra torsional strength compared to API connection

- Increased anti-fatigue performance

- While maintaining required torsional strength, it can:

- minimize the tool joint OD

- maximize the ID

- Reduced internal erosion and improved hydraulic efficiency

Product Specifications

HLST® series including HLST®24, HLST®26, HLST®31, HLST®36, HLST®39, HLST®40, HLST®46, HLST®52, HLST®57, HLST®66, etc.

For HLST® connection performance, please see Table A.7 or Table B.7 in our DRILLING TOOLS BROCHURE.

HLIST® series including HLIST®38, HLIST®39, HLIST®46, HLIST®50, HLIST®54, HLIST®57, etc.

For HLIST® connection performance, please see Table A.8 or Table B.8 in our DRILLING TOOLS BROCHURE.

Hilong Gas Sealed Connection: HLDT-GS®Series

HLDT-GS® can be used in Drill Stem Testing (DST) operations, hydraulic fracturing, well completion, and underbalanced drilling with high metal-to-metal internal seal performance under gas pressure loading. Compared to the traditional single-function drill string, using HLDT-GS® drill string can save time and reduce cost.

Product Advantages

Compared to API connections, HLDT-GS® has the following features:

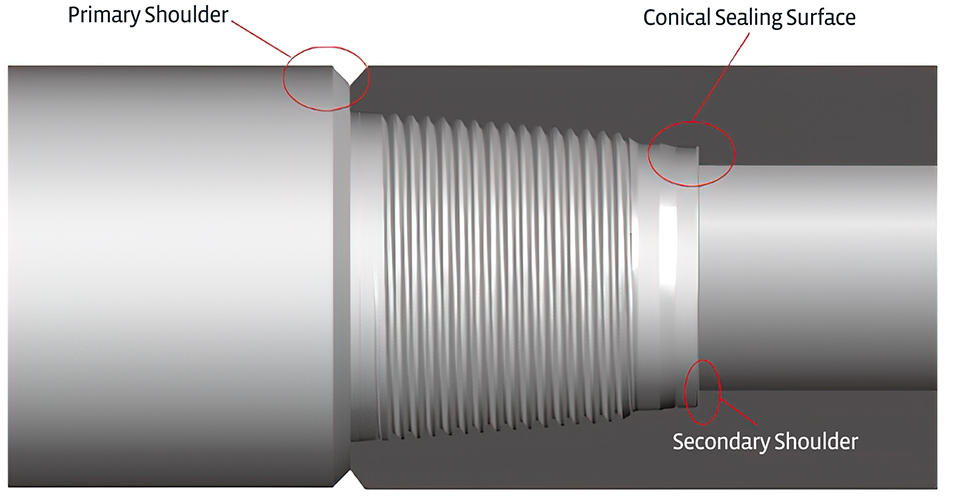

- The use of a double-shouldered compound sealing structure allows the smooth transition of inner diameter, and smooth metal surface elastic interference fit achieves metal-to-metal seal.

- Seal integrity is not affected by tensile load and multiple drilling trips.

Product Specifications

HLDT-GS®26, HLDT-GS®31, HLDT-GS®38, HLDT-GS®40, HLDT-GS®46, HLDT-GS®50, HLDT-GS®55 and HLDT-GS®65, the sealing structure can be applied to API Spec 7-2 and non-API rotary shouldered connections.

Product Performance

Superior sealing performance with gas sealing capacity up to 15000 PSI (105MPa).